Introduction

Chimney liners play a crucial role in ensuring the safe and efficient operation of fireplaces and stoves. Understanding the different types of chimney liners, their benefits, and when to replace them is essential for maintaining a home’s safety and performance. With the right knowledge, homeowners can make informed decisions that protect their property and enhance their heating systems.

Different materials and designs of chimney liners cater to various needs and conditions. Liners can prevent dangerous gases from leaking into the home, improve draft efficiency, and extend the lifespan of the chimney. Recognizing the signs of wear can save homeowners from costly repairs and safety hazards.

Choosing and maintaining the appropriate chimney liner involves careful consideration and regular inspections. Homeowners should be aware of the right materials for their specific heating appliances and how to ensure proper installation. Making these choices wisely can lead to a safer and more efficient home heating experience.

Key Takeaways

- Chimney liners are vital for safety and efficiency.

- Signs of damage indicate the need for replacement.

- Proper installation and maintenance enhance liner longevity.

Fundamentals of Chimney Liners

Chimney liners are essential components of venting systems for fireplaces and stoves. They provide both safety and efficiency by ensuring that the flow of combustion gases is properly managed. Key aspects include their purpose, material options, and various types available.

Purpose and Functions

Chimney liners serve multiple critical purposes. They protect the masonry of the chimney from heat and corrosion caused by combustion gases. The liner also helps to reduce creosote buildup, which is a key factor in chimney fires. Additionally, liners improve the draft, allowing smoke and gases to exit the home more efficiently. By maintaining a consistent temperature, they minimize condensation and maintain proper ventilation. This not only enhances the safety of the chimney but also increases the efficiency of the appliance it serves.

Materials Used in Liner Construction

Chimney liners are made from several different materials, each with unique properties. Clay tiles are a traditional option, known for their durability and resistance to heat but can crack over time. Stainless steel liners are popular for their flexibility and corrosion resistance, making them suitable for various fuels, including wood and gas. Aluminum liners are lightweight and easy to install but are typically only suitable for gas applications. Additionally, cast-in-place liners use a specialized mix for custom shapes and are effective for repairing damaged chimneys. Choosing the right material is crucial for ensuring the liner’s longevity and effectiveness.

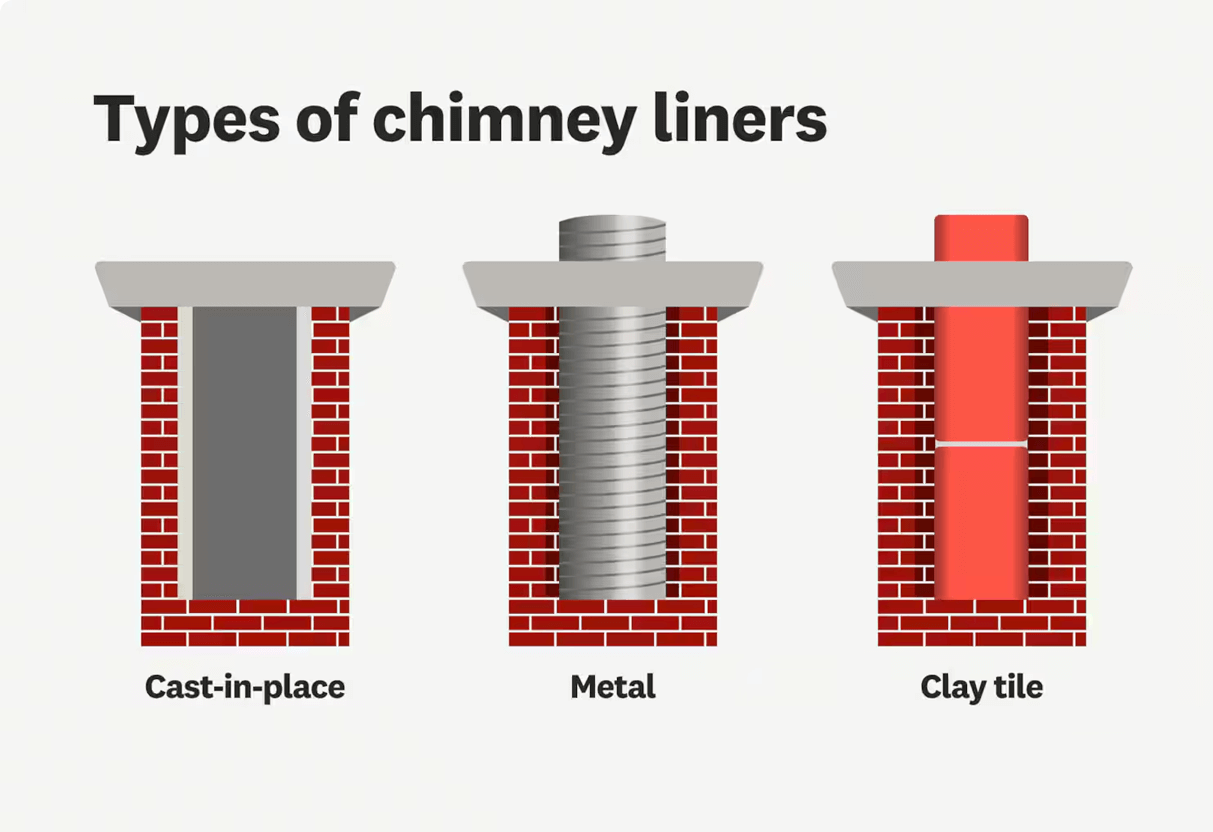

Types of Chimney Liners

Chimney liners can be categorized into several types based on their design and installation method. Single-wall liners are commonly used for relining existing chimneys and provide a smooth surface for better draft. Double-wall liners offer enhanced insulation and are useful in high-efficiency appliances. Flexible liners are suited for complex chimney shapes and can be easily adjusted during installation. Cast-in-place liners offer a custom-fit solution and can be poured directly into existing chimney walls for a seamless finish. Each type has advantages and limitations, making it important to assess the specific needs of the chimney system before selection.

Advantages of Chimney Liners

Chimney liners provide several critical advantages for both safety and efficiency in chimney systems. These benefits include enhanced safety from potential fire hazards, improved energy efficiency during heating, and an extended lifespan for the chimney structure.

Enhanced Safety

Chimney liners play a vital role in preventing dangerous situations. They create a barrier between the flue gases and the chimney walls, reducing the risk of heat transfer.

This barrier minimizes the likelihood of combustible materials igniting, significantly lowering the risk of chimney fires. According to the National Fire Protection Association, improper chimney maintenance and lack of liners contribute to numerous house fires annually.

By properly lining the chimney, homeowners can safeguard their properties and loved ones. Regular inspections and maintenance of chimney liners further enhance this safety.

Improved Efficiency

The installation of a chimney liner can lead to greater heating system efficiency. A properly sized liner helps maintain optimal flue gas temperature, ensuring efficient venting of exhaust gases.

This can result in reduced fuel consumption, ultimately saving money on energy bills. Additionally, proper liner installation minimizes the risk of blockages that can hinder airflow.

By ensuring consistent airflow, the heating system runs more effectively. Homeowners may notice improved performance from their fireplaces or stoves, leading to a more pleasant indoor environment.

Extended Chimney Lifespan

Chimney liners contribute significantly to extending the lifespan of chimney structures. By protecting the interior walls from corrosive elements present in flue gases, liners help maintain the integrity of the chimney.

This prevention limits damage from moisture, soot, and acidic byproducts that can erode brick and mortar over time. Regular use of a chimney liner can delay costly repairs or replacements.

It also provides an opportunity for more straightforward cleaning since many liner types are smooth and easy to maintain. Investing in a high-quality chimney liner can thus yield long-term benefits, preserving the functionality of the chimney for years to come.

Signs Your Chimney Liner Needs Replacement

Several indicators can signal that a chimney liner requires replacement. These signs include visible deterioration, performance issues, and results from professional inspections. Observing these factors can help maintain chimney safety and functionality.

Visible Deterioration

Visible damage to the chimney liner is one of the clearest signs it needs replacement. Homeowners should look for cracks, gaps, or corrosion on the liner’s surface.

- Cracks can allow harmful gases to escape into the home.

- Corrosion is often found in metal liners, which can lead to complete failure.

If a homeowner notices peeling or flaking materials, it is also a cause for concern. Regular visual checks can help catch these signs early, preventing more significant issues.

Performance Issues

Performance-related concerns can indicate that the chimney liner is compromised. Homeowners may notice:

- Increased smoke in the living area, suggesting inefficiency in venting.

- Soot buildup in unusual amounts, signifying that combustion is not occurring correctly.

Strange odors emanating from the chimney or a lack of proper draft can also suggest liner issues. If the fireplace or heating appliance struggles to function correctly, it may be time for an assessment.

Professional Inspection Results

Professional chimney inspections can reveal critical issues not easily seen. These evaluations utilize special tools to check the structural integrity of the liner.

If a professional indicates that there are signs of significant damage, it is essential to take this seriously.

Some inspectors provide detailed reports highlighting:

- Areas of concern

- Recommendations for replacement

Regular inspections every year can help identify problems before they escalate. Homeowners should keep these evaluations in mind for maintaining the safety and performance of their chimney systems.

Selecting the Right Chimney Liner

Choosing the appropriate chimney liner involves evaluating individual needs, comparing materials, and understanding specific dimensions. These considerations ensure safety and efficiency for the chimney system.

Assessing Your Chimney’s Needs

Before selecting a chimney liner, it is vital to assess specific requirements. Factors such as the type of fuel used (wood, gas, or oil) and the age of the chimney play significant roles.

For example, a wood-burning appliance might necessitate a different liner compared to a gas furnace.

A thorough inspection can determine if there are cracks, creosote buildup, or structural issues. Consulting a professional can provide insights into any necessary repairs that may affect liner installation.

Understanding these needs helps in choosing a liner that enhances performance and maintains safety standards.

Comparing Liner Materials

Chimney liners are available in several materials, each with its benefits and drawbacks. The three main types are stainless steel, clay tile, and fiberglass.

- Stainless Steel: Durable and resistant to condensation, ideal for both gas and wood-fueled systems.

- Clay Tile: Traditional choice, offers good heat resistance but may crack over time.

- Fiberglass: Lightweight and resistant to chemicals, suitable for certain applications but less common.

Considering the application and location of the chimney will help in making a more informed choice. Evaluate factors such as cost, longevity, and resistance to corrosion while comparing materials.

Understanding Liner Dimensions

Proper dimensioning is crucial for fireplace efficiency. A chimney liner must match the flue’s size for optimal performance.

Key measurements include the height, width, and diameter of the existing flue. It should be a snug fit to ensure proper drafting and to prevent dangerous gases from leaking into the home.

Chimney liners typically come in various sizes tailored to different flue dimensions. Selecting the correct size minimizes the chances of chimney fires and enhances heating efficiency. Employing a professional measurement can eliminate guesswork and ensure that the liner fits correctly.

Installation and Maintenance Tips

Effective installation and maintenance of chimney liners are critical for ensuring optimal performance and safety. This section addresses key aspects, including professional installation considerations, necessary routine maintenance, and the importance of annual inspections.

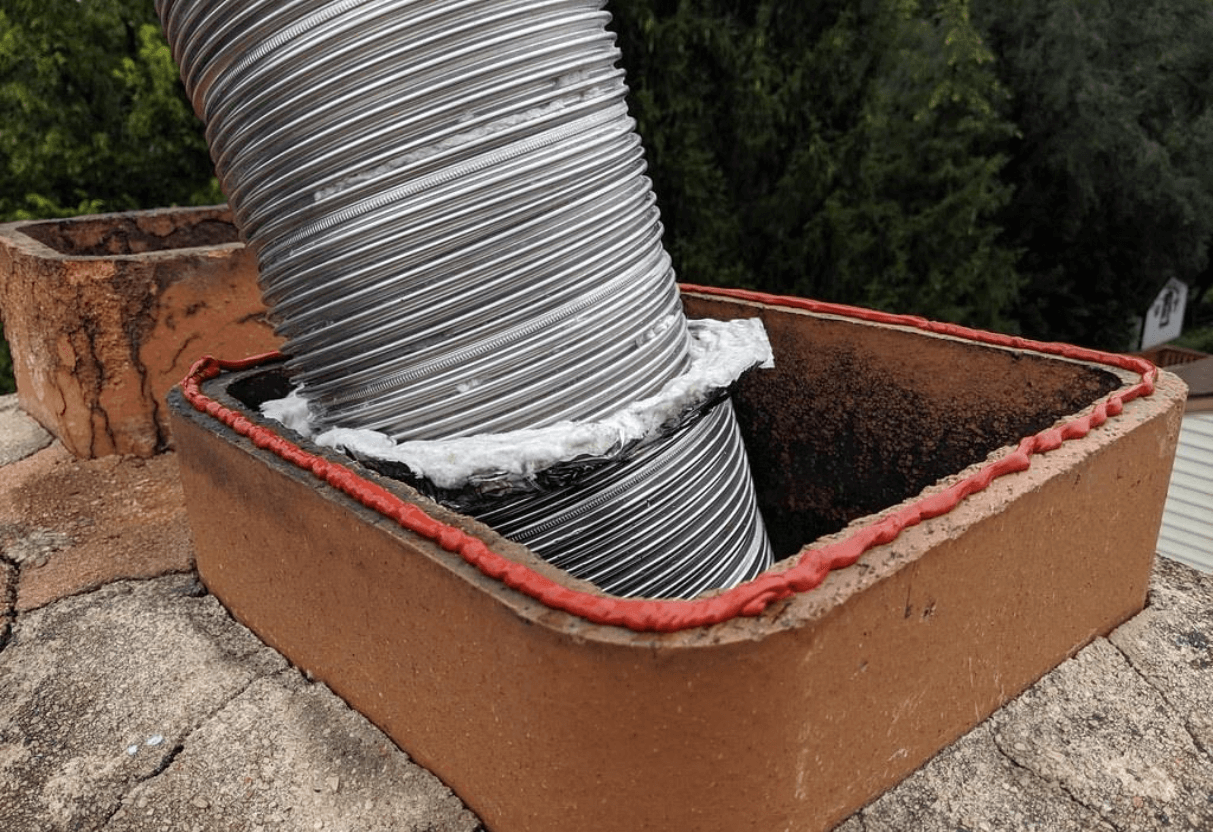

Professional Installation Considerations

Choosing a qualified professional for chimney liner installation is essential. Installers should possess experience and knowledge of building codes and safety regulations.

The liner material significantly impacts installation techniques. For example, stainless steel liners require specific flue size adjustments, while ceramic liners might need unique support structures.

A proper installation ensures secure connections and minimizes risks of leaks or blockages. Homeowners should verify that the installer provides a warranty and adheres to standards, ensuring the liner functions correctly for its intended service life.

Routine Maintenance and Care

Routine maintenance is crucial for prolonging the life of chimney liners. Homeowners should regularly inspect for signs of wear, such as cracks or corrosion in the liner.

Removing debris and creosote buildup is vital for preventing blockages. Utilizing a chimney brush and vacuum system can facilitate a thorough cleaning.

It’s essential to routinely check the liner’s connection to the flue. If gaps or deterioration appear, homeowners should address these issues promptly to avert further damage or potential hazards.

Annual Inspections and Cleaning

Annual inspections by a certified chimney sweep are recommended. This ensures comprehensive evaluation of the liner’s integrity and efficiency.

During inspections, sweepers check for deterioration, blockages, and structural issues. If problems are identified, immediate action can prevent more extensive repairs.

Homeowners should schedule cleanings based on usage patterns. Frequent use may require more regular maintenance to maintain safety. Proper cleaning and inspection ultimately protect the home from fire risks and enhance the longevity of the chimney liner.

Frequently Asked Questions

This section addresses common inquiries regarding chimney liners, covering types, benefits, replacement indicators, potential risks, inspection frequency, and important considerations when choosing a liner.

What are the different types of chimney liners and how do they differ?

Chimney liners can be categorized into three main types: clay tile, stainless steel, and cast-in-place liners. Clay tile liners are traditional and durable but may crack over time. Stainless steel liners are versatile, resistant to corrosion, and suitable for a variety of fuels. Cast-in-place liners create a seamless, custom-fit design but require professional installation.

What are the primary benefits of installing a chimney liner?

Installing a chimney liner enhances safety by containing flue gases and preventing them from escaping into the home. It also improves the efficiency of the chimney system, reducing the risk of chimney fires. Additionally, a liner protects the chimney structure from heat and corrosion, extending its lifespan.

How can I determine if my chimney liner needs to be replaced?

Signs that a chimney liner needs replacement include visible cracks or gaps in the liner, rust formation, or the presence of soot buildup. Unpleasant odors or smoke backing up into the home can also indicate problems. A professional inspection can provide a thorough assessment of the liner’s condition.

What are the potential risks associated with not replacing a damaged chimney liner?

Failing to replace a damaged chimney liner can lead to serious safety hazards. These risks include the potential for chimney fires, carbon monoxide leaks, and structural damage to the chimney. Inadequate venting can also compromise the efficiency of the heating system, leading to increased energy costs.

How often should chimney liners be inspected and maintained?

Chimney liners should be inspected at least once a year, preferably before the heating season. Maintenance tasks may include cleaning the liner and checking for signs of damage. Regular inspections can help identify issues early and prevent costly repairs.

What should I consider when choosing a chimney liner for my home?

When selecting a chimney liner, homeowners should consider the type of fuel being burned, the size of the chimney, and local building codes. Durability and resistance to corrosion are also important factors. Consulting with a professional can help determine the best liner for specific needs.